Diesel Engine Component And Functions – The diesel engine is an internal combustion engine that utilizes high fuel and compression fuels to perform the combustion process. This diesel engine has a working principle that is almost identical to gasoline engines, but there are some differences in the business step of the machine, such as the use of spark plugs on gasoline engines that are not found in diesel engines.

The components of this diesel engine have some differences and similarities with gasoline engines. The difference lies in the material of the manufacture, where the machine is harder than the gasoline engine. While the association is having 4-and 2-no work system. So the name of the component that is in the diesel engine is much the same as gasoline engine. And these components have the same tasks and functions on each machine.

On this occasion will only discuss the main components of the diesel Engine 4 No and its function. The main components of the diesel engine that will be described below have a direct connection with the combustion cycle on the 4-Tak diesel engine. Then, what are the names of the 4-part diesel engine component? See the following description.

Diesel Engine Component And Functions

1. Cylinder Block Assy

Cylinder block is the main component of 2-and 4-and-no-motor fuel. on a motor burn, this component becomes a component used to put a variety of other machine components that support the working process of the machine. In general, cylinder block on each machine has the same shape, which is different in size detail that has been adjusted with other components that will be placed in the cylinder block.

The material used for the manufacture of cylinder blocks is cast iron and mixing of other metals with high precision. In general, the engine components located in this cylinder block are:

a. Cylinder Liner

Cylinder liner is part of cylinder block assy which is tubular. This component is used as a piston step. The Cylinder liner is made of a mixture of iron and aluminum that is heat resistant and high pressure. The installation of cylinder liner is usually in press, so usually to remove it is a bit difficult and must use special tools.

b. Water Jacket

The water jacket is a hole in the crankcase (block machine) that surrounds the cylinder liner. Its function is to place the cooling water inside the engine block. With the circulation of water through this water jacket, the process of cooling machine can be maximal.

c. Oil Feed Lines

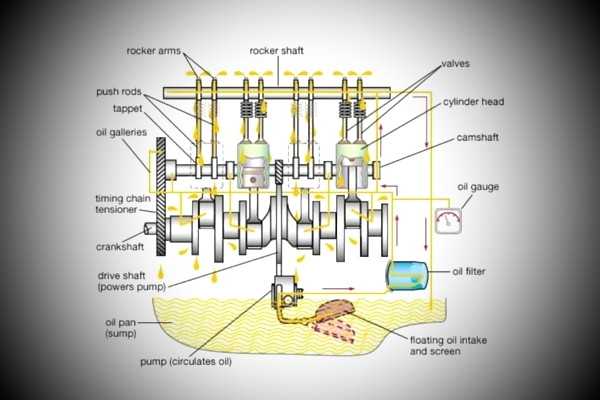

The Feed liner oil is a small gap that serves as a circulation hole in the engine oil located on the cylinder block. The process of engine oil travel from cylinder head to crankcase or vice versa, will pass oil feed lines in the finulation.

2. Cylinder Head Assy

Culinder Head is the head of diesel engine. These components are located on the front or top of the machine depending on each machine. The material used for the manufacture of cylinder head is the same as cylinder block, which is a strong cast iron material. In cylinder head components, there are several other components, such as valve and spring valve, rocker arm and the fuel chamber.

a. Valve and Spring Valve

In general, the valve consists of valve inlet and outlet. Both valves are components that serve as a door that serves to open and close the intake and exhaust channels when the machine works. While the spring valve serves as a suppressor valve inlet and oulet to be perfectly sealed.

b. Rocker Arm

Rocker arm is a component that growts step valve to be able to open and close. While the move rocker arm is arranged by Camchaft, so it has a regular time lag when pressing and removing the valve. Rocker Arm also has a gap distance adjustment system with the end of the valve rod, so that between the valve inlet and outlet can close simultaneously at a certain time lag.

c. Burn Room

The combustion chamber is a small space that the engine uses to do the burning. The fuel chamber is also a boundary of the piston’s dead point when doing the engine business process. This fuel room is usually only available in the diesel engine indirect injection type.

3. Piston Assy

The Piston is a diesel engine component that serves to adjust the volume inside the cylinder liner. When the piston moves from the top dead point to the lower dead point, the volume inside the cylinder liner will enlarge. This occurs when the machine performs an air suction into the cylinder liner. Whereas when the piston moves from the bottom dead point to the top dead point, the volume inside the cylinder liner will shrink. This occurs when the moving piston makes compression and when it removes residual gas combustion.

In general, piston fittings consist of piston rings, piston pins, and connection road. And the three components have their own duties and functions.

a. Piston Ring

In general, diesel engines 4 do not have three types of piston rings, namely the main ring, compression ring, and ring oil. The main piston ring is the piston ring located at the very top. Serve as a compression holder so as not to leak. The Ring is rather loud and strong.

Compression piston ring has the task of making compression and preventing air leakage when the compression step. The ring has elastic properties and is usually located halfway between the main ring and the oil ring. Oil Piston ring is the bottom of the ring. Its function is to prevent the engine oil from the crankcase from entering the fuel chamber.

b. Piston Pin

The piston pin is a tube-shaped pin rod that serves to connect the piston with the connection road. Location of the piston pin is inside the piston. And to lock these piston pins usually use snapring.

c. Connecting Rod

Connecting rod or piston stalk is a component that serves to connect the piston with crankshaft. The Connection rod with the crankshaft is what will convert the piston up-down movement into a round that is then passed on to other moving components.

4. Camshaft

Camshaft is a kompcomponent in charge of the step rocker arm in opening and closing valve (valve). To connect the camshaft with rocker arm, usually used timing chain or push road.

5. Crankshaft

The crankshaft or Posros is a diesel engine component in charge of turning the piston step down into a lap motion. This crankshaft is made of high quality cast iron, so that it can withstand the moment given by the piston drive. The crankshaft has parts in the trunk, including:

a. Crank Pin

Crank pin is part of crankshaft connected with big end on connecting rod. On the crank pin is usually a hole as a circulation of the crankshaft lubrication.

b. Crank Journal

The crank journal is a part that serves as the crankshaft shaft. This is where the main bearings are attached and installed on the crankcase (the engine block).

c. Crank Arm

The crank arm is the part that connects the crank pin and crank journal. The Crank arm is also often used as the connecting arm and is where the weight balance mounts.

d. Weight Balance

The Weight balance is a component of the crankshaft that serves as the counterbalance of the engine and also to drain the oil from the crankcase to all parts of the crank.

6. Oil Pan (Carter)

In some diesel engines there are equipped with a charter. This Charter function is as a machine oil container. This component is generally made of thin-sized steel plates attached to the bottom of the crankcase. On the Charter is also the place where the suction line of the oil pump is tasked to drain lubricating oil to all parts of the diesel engine.

7. Flywheel

Flywheel is a diesel engine component that serves as the engine’s round balancer. This crazy wheel is made of solid iron that can save the moment. Therefore, this component can balance the rounds when the machine is running.

In addition to counter balancing, this crazy wheel is also tasked with assisting early rounds when powering the engine. It can be proved from a car diesel engine that has a gear connected to the dinamo starter. While the Dinamo starter is a component used to animate the machine.

8. Fuel System Assy

The fuel system is a series of components that begin from the fuel tank to the injector. Diesel engine fuel system is tasked with supplying solar fuel into the combustion chamber. Based on how it works, the fuel system in diesel engines is two kinds, common rail and conventional systems. On common rail diesel engines, fuel supply is more efficient and akuart, because it carries the computerized control. Whereas on conventional diesel engines can be said to be still manual follow the movement of the engine rotation.

The diesel engine work cycle is strongly influenced by the functionality of each component. Therefore, if one component is damaged, the diesel work process will be problematic. Therefore, do regular maintenance of the diesel engine to keep its performance awake. That is diesel engine component and functions. Hopefully it can be a useful insight.

More Articles :

- Diesel Engine Combustion System

- How The Diesel Engine Works

- Differences Diesel Engine And Gasoline Engine

- How To Service Kubota Diesel Engine

- How To Repair the Diesel Engine Hard To Live